Offshore decommissioning & recycling specialist

Does your offshore equipment need replacing? And are you looking for a party to take care of decommissioning the offshore structure? Meet Jansen Recycling Group. We have been specialising in dismantling offshore structures since 2013 and have our very own dismantling yard in Vlaardingen. This yard has its own river port and a direct link to the North Sea, and it is fully liquid-proof. We have all the certificates and permits required for safe and responsible dismantling of large and complex structures. We will take care of the whole process for you, from decommissioning to sorting and recycling the materials recovered. Curious about what we can do? Contact us without any obligations.

Offshore constructions

Ship wrecks

Oil- and gas platforms

Wind turbines

Grillage and seafastening

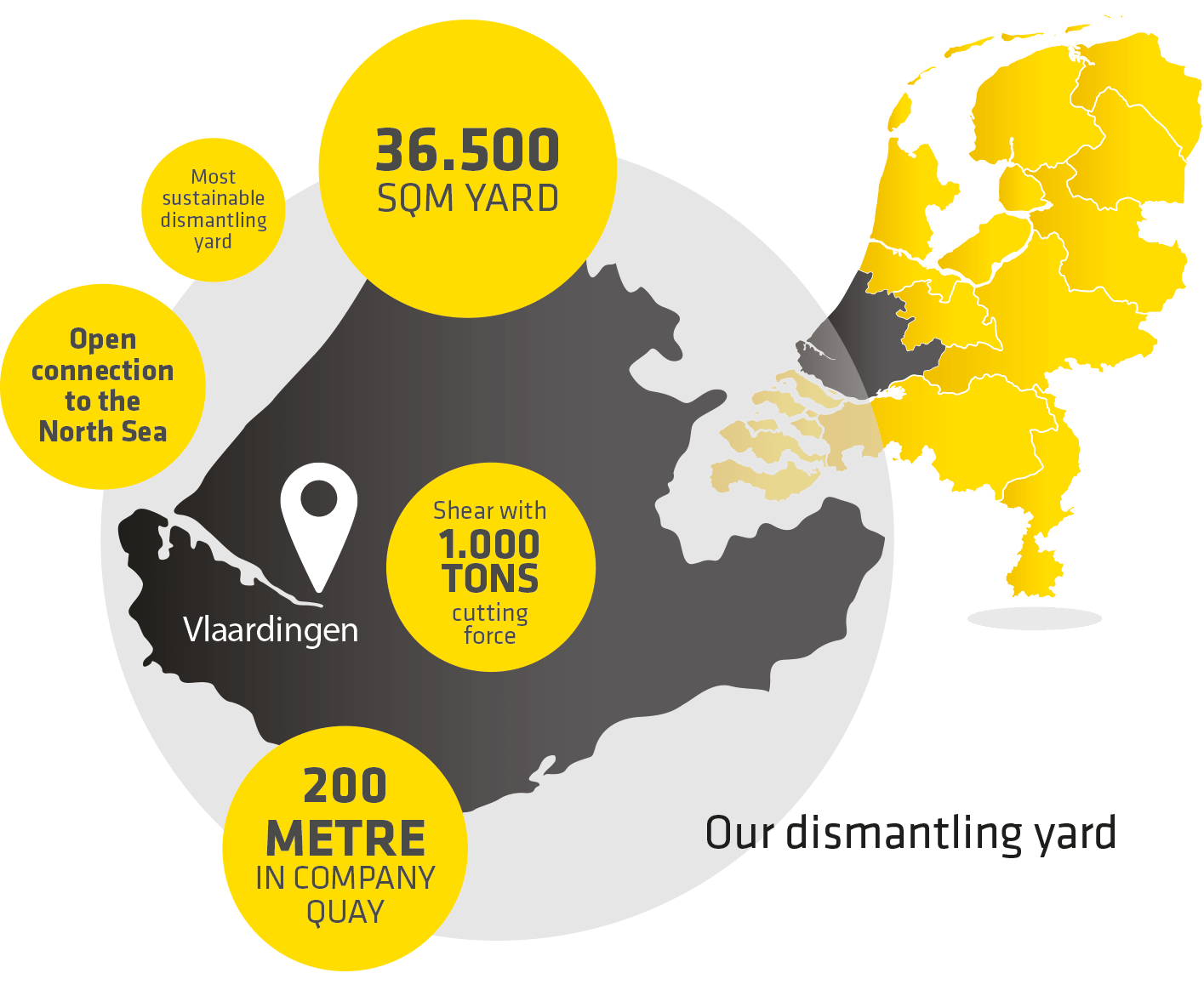

Dismantling yard Vlaardingen

Located in the Port of Rotterdam

Open connection to the North Sea

Surface area of 36,500m² with its own 200-metre quayside

Liquid-proof, certified site

On-site water-treatment system

Dismantling various kinds of offshore equipment

Has your offshore rig reached the end of its life cycle? JRG is your go-to partner for both the dismantling and the recycling of oil and gas rigs, ships or other kinds of offshore structures. We can also take care of offshore wind farm decommissioning and recycling for you. What sets us apart is that we can also recycle wind turbine rotor blades.

Offshore decom process: from dismantling to recycling

We will take care of the whole offshore decom process, from dismantling the structure to sorting, processing and recycling the materials recovered. Needless to say, we will minimise the environmental impact at all times. And we will also do all the paperwork for you. Here’s what our offshore decom process looks like:

Step 1 | First of all, we want to know all the technical details of the structure. We ask our clients lots of questions to find out everything there is to know about the structure.

Step 2 | Next, we write a project offer. Our proposal covers the kind of work we expect to be required and what procedure we will be using. It also lets you choose whether or not to maintain ownership of the offshore structure until it has been processed into secondary raw materials. That’s up to you.

Step 3 | This step is when you assess our proposal. If we are on the same wavelength, we will draft a contract and get started decommissioning your offshore structure.

Step 4 | The structure will be taken to our yard in Vlaardingen, where it will be dismantled. We sometimes engage a third party for that.

Step 5 | We sort all the materials recovered from the dismantled structure and check them for radioactivity. We recycle all the iron and non-ferrous materials ourselves by turning them into materials that are ready to be processed at a smelting plant.

Step 6 | We calculate the scrap value. The resulting amount will be paid into your bank account within three days of clearance.

Step 7 | You will receive a final report listing exactly what materials we have recycled and where they went. We always aim for a closed mass balance, i.e. to recycle as much of the metal as possible.

NOGEPA-certified

You can count them on the fingers of one hand: Dutch companies that have been audited by NOGEPA*. JRG is one of them. Take a look at all our certifications >

*NOGEPA sets safety standards in the offshore world.

Liquid-proof dismantling yard with its own water purification system

Our dismantling yard in Vlaardingen is entirely liquid-proof, meaning that we can collect all liquids, i.e. both leaked oils and contaminated water. After collecting such liquids, we filter the water using our very own water purification system. Our system is of such good quality that we are allowed to discharge the purified water directly to the sewage system and/or the river. In short: we leave no stone unturned during the dismantling and recycling process to prevent environmental pollution and control risks.

The best price for your metals

Not only can you hire us for offshore decommissioning, you can also turn to us for the recycling of your metals into secondary raw material. Our recycling process is as efficient as it is meticulous, so as to make sure that no valuable materials are lost. Additionally, with our in-depth knowledge of ferrous metals and non-ferrous metals we can ensure that you always get the best price for your metals.

Want to partner with us?

Looking for a partner for your offshore decommissioning project? We would be happy to help you consider your options. Contact us without obligations to find out what we can do.

Project highlights

Jansen Recycling Group has carried out many different projects over the last few decades. A selection of these:

Dismantling old Botlekbrug

At the beginning of 2018, we successfully dismantled the old bridge sections of the old Botlekbrug at our yard. Project partner: Vlasman. Total tonnage: 6,000 tons.

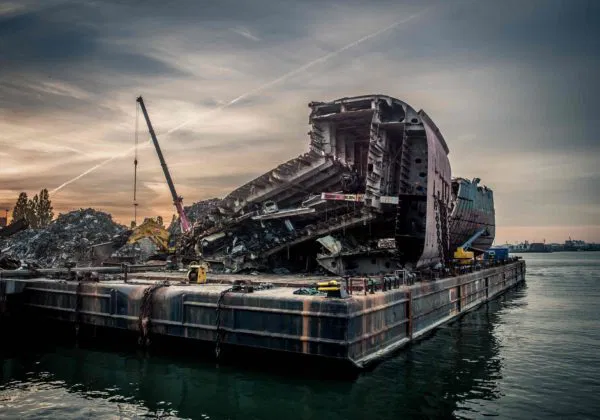

Decommissioning of MV ‘Baltic Ace’

Under commission by Boskalis and Rijkswaterstaat, we demolished the wreck of the sunken car carrier MV ‘Baltic Ace’, which was carrying 1,417 new cars. Project partner: Democom. Total tonnage: 11,000 tons.

Demolition of Scheveningse Pier

In 2017, we dismantled the Stalen Eiland, part of the Scheveningse Pier. Project partner: Kruiswijk. Total tonnage: 1,000 tons.

Demolition of ship wreck 'Jan Breydel’

Under commission by Boskalis and Rijkswaterstaat, we dismantled the fishing trawler Jan Breydel in 2013. This wreck had lain on the seabed for some 25 years, right in the middle of the navigable channel leading up to the Port of Amsterdam.

Dismantling of wind turbines

The first turbines in the Netherlands are now being replaced with larger, more efficient turbines with a higher yield. At the end of their design life, more and more wind turbines are being scrapped. Jansen Recycling Group has the perfect setup for scrapping wind turbine towers and the turbines themselves as safely and efficiently as possible.

Demolition of MV ‘Ping An’

The Chinese cargo ship ‘Ping An’ ran aground in 1965 in a storm along the coast of South Holland. Re-floating was not possible, so H.P. Heuvelman, the grandfather of the current generation of Jansens, demolished and processed the ship.